The Temperature Legend of Industry: Teflon Tube Debuts

On the industrial stage, temperature is often a highly challenging factor. From extremely cold freezing environments to hot high-temperature work areas, equipment and pipelines are facing severe challenges. So, is there a material that can work stably in such a wide temperature range? The answer is Teflon tubing.

Teflon tube, also known as polytetrafluoroethylene tube, can be called the "temperature warrior" in the industrial field. Its presence covers many key industries such as chemical, electronics, aerospace, etc., shouldering the responsibility of transporting various media and ensuring the stable operation of equipment. In chemical production, it can resist the erosion of high-temperature chemical reagents; In electronic device manufacturing, it provides reliable protection for precision instruments. Imagine in a complex industrial system, PTFE tubing is like a silent guardian, ensuring the smooth flow of the entire process regardless of the harsh environmental temperature. Its existence not only improves the efficiency of industrial production, but also ensures the quality and safety of products. Therefore, PTFE pipes have become the preferred material for many engineers and enterprises. Figure 1: Application of PTFE pipes in industrial pipeline systems.

What did it go through from 200 ℃ to 260 ℃?

In the ultra-low temperature environment of -200 ℃, PTFE pipes are like tough polar explorers, surrounded by a sea of ice and snow, and other materials may have already become fragile and fragile, like glass that can break at a light touch. However, PTFE tubes still maintain good flexibility and mechanical properties, with a tight and stable molecular structure that will not undergo brittle cracking due to low temperatures. They can still stably transport special low-temperature liquids, providing guarantees for scientific research experiments and low-temperature industrial production.

When the temperature soared to 260 ℃, the PTFE tube transformed into a fearless high-temperature warrior. Beside the high-temperature chemical reactor, the heat wave is rolling, and ordinary pipelines may soften and deform, and even be corroded by chemicals at high temperatures, leaving them riddled with holes. Thanks to its stable chemical properties and high temperature resistance, PTFE pipes do not melt or decompose at high temperatures, effectively resisting the erosion of high-temperature chemical reagents and ensuring the smooth progress of chemical production.

What secrets are hidden behind such a huge temperature range, from extreme cold to scorching heat, that PTFE pipes can easily cope with?

The secret behind the miraculous performance

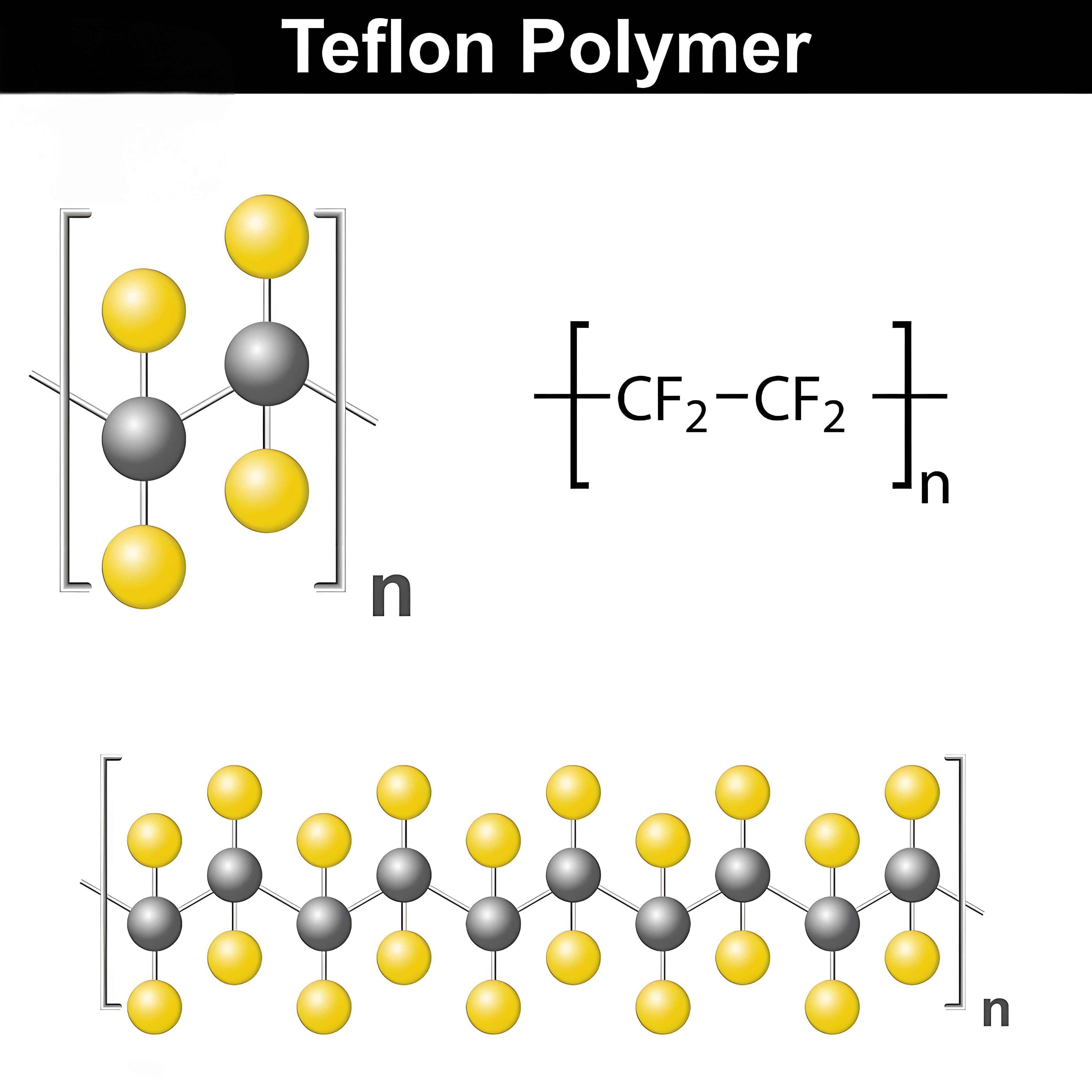

The reason why PTFE tubes can perform well in the extreme temperature range of -200 ℃ to 260 ℃ is due to their unique molecular structure. Teflon, also known as polytetrafluoroethylene, has a molecular chain composed of tightly arranged carbon and fluorine atoms, forming extremely stable carbon fluorine bonds. This type of chemical bond has extremely high energy, like a sturdy chain that firmly connects molecules together, making it difficult for the molecular chain to break even at high temperatures. Even at a high temperature of 260 ℃, the carbon fluorine bond can still hold its position, maintaining the stability of the molecular structure and ensuring that the PTFE tube does not melt or decompose.

Meanwhile, the interaction force between the chains of PTFE molecules is relatively weak. This may seem like a weakness, but it is actually its' secret weapon 'for adapting to extreme temperatures. At ultra-low temperatures of -200 ℃, the weak intermolecular forces prevent the PTFE tube from becoming stiff and fragile due to temperature reduction, and still maintain a certain degree of flexibility to prevent its use from being affected by low-temperature brittleness. It's like a soft rope that can maintain its bendability even in cold environments. The advantage in molecular structure is the key factor that makes PTFE tubes the preferred choice for industrial temperature resistance, allowing them to perform well in temperature ranges that other materials are hesitant to use. Schematic diagram of the molecular structure of PTFE

Strength out of the circle, application award

Teflon pipes have shown outstanding performance in many industrial fields due to their excellent temperature resistance.

In the chemical industry, it is a powerful assistant for transporting corrosive chemicals such as strong acids and alkalis. For example, in a sulfuric acid production plant, from the transportation of raw materials to the storage of finished products, PTFE pipes run through it. It can resist the strong corrosiveness of sulfuric acid at high temperatures, ensuring the safety and stability of the production process, avoiding leakage accidents caused by pipeline corrosion, and ensuring the continuity of chemical production. Figure 3: Application of PTFE pipes in the chemical industry.

In the field of electronics, PTFE tubes are also indispensable. In the manufacturing process of circuit boards, precise control of the transportation of various chemical reagents is required. The low solubility and corrosion resistance of PTFE tubes ensure the purity of chemical reagents, avoid contamination of electronic components, and thus improve the quality and performance of electronic products. Inside precision electronic instruments, PTFE tubes provide protection for the circuit, allowing it to operate stably in different temperature environments and reducing signal interference.

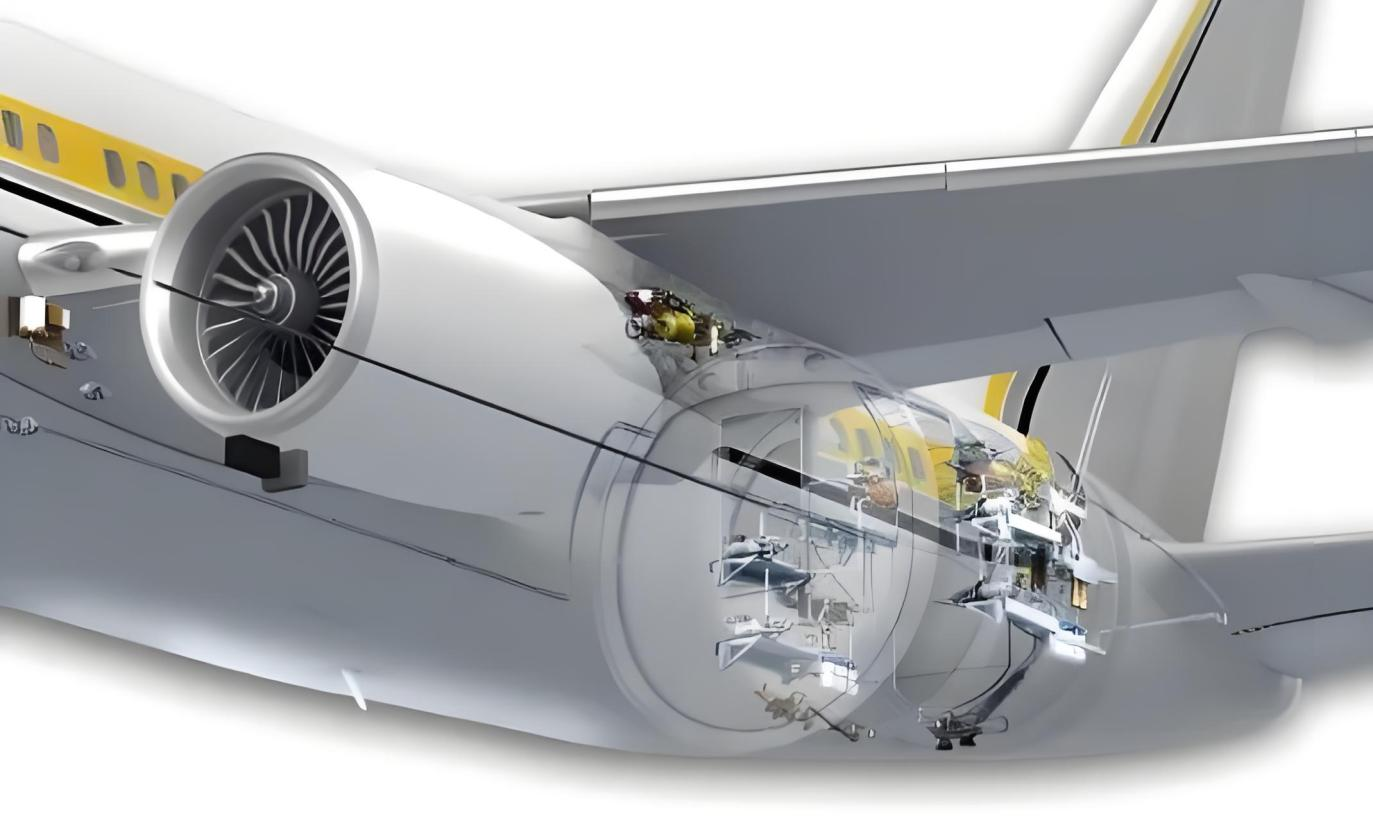

The aerospace industry has extremely high requirements for the performance of materials, and PTFE pipes are also showing their skills here. In the hydraulic system of an aircraft, it can withstand low temperatures and high pressures at high altitudes, stably deliver hydraulic oil, and ensure the safety of the aircraft's flight. In the electronic equipment of satellites, PTFE tubes protect critical circuits, enabling them to withstand the alternating high and low temperatures in harsh space environments and ensuring the normal operation of satellites.

From chemical engineering to electronics, and then to aerospace, PTFE pipes have become an indispensable key material in industrial production due to their excellent temperature resistance, providing a solid guarantee for the development of various industries.

Teflon tube, promising for the future

Teflon tubing has become a leader in industrial temperature resistant materials due to its excellent performance at extreme temperatures ranging from -200 ℃ to 260 ℃, unique molecular structure, and wide range of applications. Its outstanding contributions in industries such as chemical, electronics, aerospace, etc. provide solid guarantees for the efficient and stable development of modern industry.

Looking ahead to the future, with the continuous advancement of technology and the sustained development of industry, the requirements for material performance will also become increasingly high. Teflon tubes are expected to make a name for themselves in more emerging fields, such as in the field of new energy, whether it is the transportation of lubricating oil in wind power generation equipment or the transportation of chemical reagents in solar cell production processes, they can all demonstrate their own advantages; In the environmental protection industry, PTFE pipes can also play an important role in sewage treatment equipment and exhaust gas purification devices. We have reason to believe that PTFE tubes will continue to shine on the industrial stage, contributing to the innovative development of various industries. Let's look forward to it creating more miracles in the future!