What is Teflon tube?

Have you ever thought about what would happen if Iron Man's suit were made of a magical plastic instead of metal? The PTFE tube we are going to talk about today has a magical quality similar to the Iron Man suit, even more durable than metal!

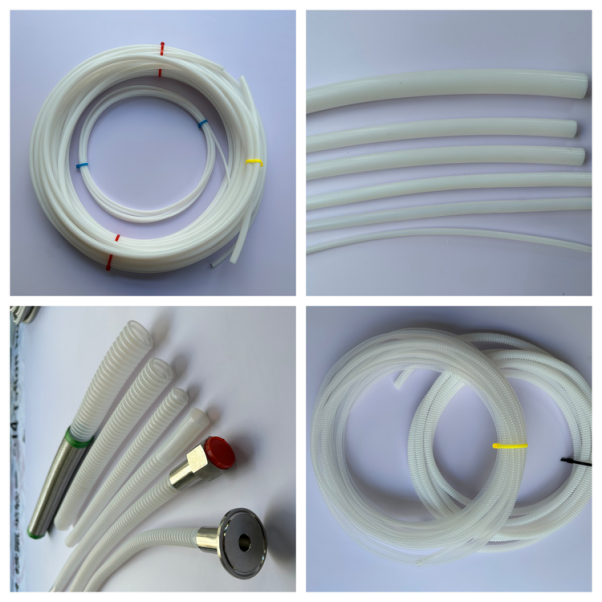

Teflon tube, scientific name polytetrafluoroethylene tube, is known as the "plastic king" in the martial arts world. It is made of polytetrafluoroethylene (PTFE) through a series of complex processes, from mixing of raw materials, extrusion molding, to drying, high-temperature sintering, and shaping, each step is crucial. [Insert a physical picture of a PTFE tube] Look, its appearance may be transparent or semi transparent, seemingly ordinary, but in fact, it has hidden mysteries.

Performance comparison between PTFE pipes and metals

Let's have a performance competition between PTFE pipes and metals to see how powerful this plastic industry "Iron Man" really is!

Let's talk about corrosion resistance first. Teflon pipes can be called "little experts in corrosion resistance". It can easily withstand the "attacks" of various strong acids and bases, such as aqua regia and hydrofluoric acid, which are a piece of cake in front of it and almost insoluble in all solvents. [Insert a picture of a PTFE tube used for transporting corrosive liquids in the chemical industry] However, metals are not so lucky. Ordinary metals will quickly be corroded into holes when exposed to strong acids and bases. Even stainless steel can only endure in some highly corrosive environments.

Looking at the high temperature resistance performance again, PTFE pipes can withstand high temperatures of 300 ℃ for a short period of time, and can be continuously used between 240 ℃ and 260 ℃. They can also work normally without brittleness even at freezing temperatures. In contrast, many metals soften or even melt at high temperatures, greatly reducing their performance.

There is also a friction coefficient. The friction coefficient of PTFE pipes is extremely low, only 0.05-0.15. When sliding under load, it is as smooth as applying oil to the soles of the feet. The friction coefficient of metals is relatively high, and in some situations where friction needs to be reduced, they are not as effective as PTFE pipes.

In terms of electrical insulation, PTFE tubes are highly non-polar materials with extremely high resistance and low dielectric constant, making them excellent electrical insulation materials. Metal is a good conductor of electricity, but using metal as insulation material would be unreliable.

Why are PTFE pipes so resistant to manufacturing?

The secret to why PTFE tubes are so resistant to manufacturing lies in their molecular structure. Its molecular main chain is composed of alternating carbon and fluorine atoms, forming a long-chain polytetrafluoroethylene structure. Each carbon atom is tightly surrounded by two fluorine atoms, forming a super strong carbon fluorine bond (C-F). Moreover, all chemical bonds of carbon atoms are occupied by fluorine atoms, without any other functional groups or side chain structures, which makes its molecular arrangement highly ordered and forms a tightly stable crystal structure. This structure is like putting an indestructible armor on the PTFE tube, endowing it with excellent chemical stability, almost no reaction with any chemical substances, and super strong corrosion resistance. The bond energy of carbon fluorine bonds is very high and they are not easily broken at high temperatures, so they can withstand the test of high temperatures. At the same time, its extremely low surface can result in an ultra-low friction coefficient and excellent non adhesiveness.

The miraculous application of PTFE pipes

With these incredible properties, PTFE pipes have demonstrated their abilities in various fields and can be called "versatile little masters".

In the aerospace field, it is the "right-hand man" of aircraft hydraulic and pneumatic systems, used to transport key gases such as fuel and oxygen, ensuring the safe operation of aircraft. For example, the oil pipes of aircraft engines use PTFE pipes, which can work stably in high temperature, high pressure, and highly corrosive environments, allowing the engine to be fully powered. [Insert a picture of using PTFE tubes in an aircraft engine]

It is also indispensable in the field of electronic appliances. Teflon tubes are high-quality insulation layers and protective sleeves for wires and cables, which improve the safety and service life of cables, just like putting a layer of "safety protective clothing" on electronic devices. In the internal cooling system of the computer, it can also serve as a heat conduction medium to help efficiently dissipate heat and prevent heatstroke.

The chemical industry is also the "main battlefield" of PTFE pipes, which are widely used to transport various corrosive liquids and gases such as strong acids, strong alkalis, salt solutions, etc. They are the "corrosion-resistant guardians" of chemical production lines. In the process of chemical reactions, it can avoid direct contact between chemical substances and the inner wall of pipelines, reducing production risks.

In mechanical manufacturing, PTFE pipes are an ideal choice for manufacturing bearings, piston rings, machine tool guides, and sealing materials due to their low friction coefficient and self-lubricating properties, making mechanical equipment operate more smoothly.

Summary and Outlook

Teflon tubing, the "Iron Man" of the plastic industry, has shone in many fields with its excellent corrosion resistance, high temperature resistance, low friction, and excellent electrical insulation performance, becoming a shining star in the field of materials science.

With the continuous advancement of technology, the performance of PTFE tubes is still being optimized. In the future, it is expected to play a key role in more fields, such as battery thermal management systems for new energy vehicles, heat dissipation and insulation protection for 5G communication equipment, and implantable medical devices in the field of biomedicine.

The development of materials science is endless, and the birth of every new material may bring about a technological revolution. Let's look forward to more magical materials like PTFE tubes appearing together, bringing more surprises and changes to our lives!